Every great heat exchanger starts at the core. It’s the heart of the system, where the actual thermal transfer happens. If the core isn’t built with precision, the entire unit’s efficiency drops.

For manufacturers, the challenge isn’t just building a core; it’s building it consistently, quickly, and cost-effectively. Whether you are running a prototype lab or a high-volume production floor, understanding the nuances of core assembly is critical.

This guide breaks down exactly what the core assembly process looks like today. We will explore the shift from manual labor to advanced automation, weigh the pros and cons of each approach, and look at the trends shaping the future of thermal management.

What Is the Core Assembly Process?

At its most basic level, core assembly is the stacking and aligning of components—tubes, fins, headers, and side plates—into a rigid matrix ready for brazing or mechanical bonding. While the end product looks like a solid block of metal, getting there requires several distinct steps.

1. Component Preparation

Before assembly begins, individual parts must be ready.

- Fin Production: Thin strips of metal (aluminum or copper) are folded into corrugated patterns. The fin height, pitch, and louvers must be exact.

- Tube Processing: Tubes are cut to length and often perforated or dimpled.

- Header Fabrication: The manifolds that distribute fluid are punched with slots to accept the tubes.

2. Matrix Stacking (The “Build”)

This is the most delicate phase. Operators or machines interleave tubes and fins. A common sequence involves placing a tube, adding a fin strip, placing the next tube, and repeating until the desired stack height is reached.

3. Compression and Squaring

A loose stack of metal won’t hold together. The assembly must be compressed to the correct core dimensions. This ensures good contact between the tubes and fins, which is vital for the brazing process later. Squaring ensures the core isn’t twisted or diamond-shaped, which would cause fitment issues in the final application.

4. Header Installation

Once the matrix is stacked and compressed, the headers (or tanks) are pushed onto the tube ends. This requires significant force and precision to avoid crushing the delicate tube ends.

5. Fixturing

Finally, the assembled core is locked into a brazing fixture. This frame holds the geometry during the high-heat brazing cycle.

Manual vs. Automated: Choosing Your Approach

Deciding how to build your cores depends on volume, budget, and flexibility needs. Let’s look at the trade-offs between a manual approach and investing in a core assembly machine.

Manual Assembly

In a manual setup, technicians stack components by hand using simple jigs.

Pros:

- Low Initial Cost: You don’t need expensive capital equipment to start.

- High Flexibility: Humans can adapt quickly. If you need to build a radiator today and a condenser tomorrow, a skilled technician can switch gears instantly.

- Ideal for Prototyping: When you only need five units for testing, hand-stacking is often the fastest route.

Cons:

- Inconsistency: Human error is inevitable. One missed fin or slightly misaligned tube can lead to a leak.

- Slow Cycle Times: It is physically impossible for a human to match the stacking speed of a machine.

- Ergonomic Risks: Repetitive stacking and heavy lifting can lead to operator injuries.

Semi-Automated and Fully Automated Assembly

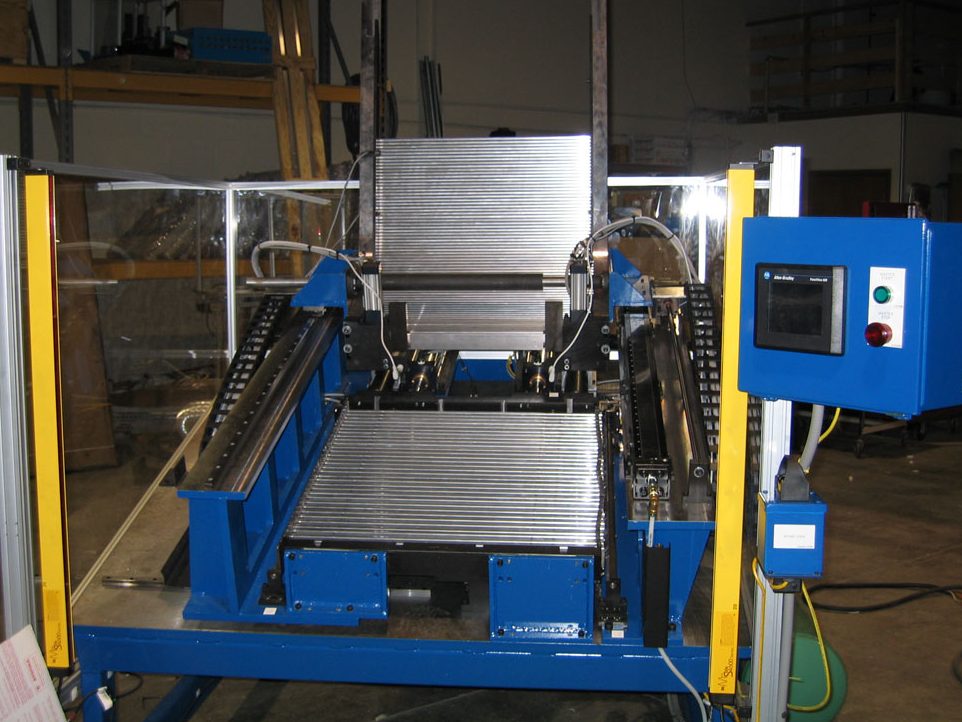

This involves using a specialized core assembly machine. These range from “fin-pushers” that help operators insert fins, to fully robotic cells that build a core from scratch without human touch.

Pros:

- Precision and Quality: Machines don’t get tired. They apply the exact same pressure and alignment for the 1,000th core as they did for the first.

- Speed: Automated builders can reduce cycle times from minutes to seconds.

- Reduced Labor Costs: While you need skilled operators to run the machine, you need fewer hands on the product itself.

Cons:

- High Upfront Investment: These machines are significant capital expenditures.

- Changeover Time: Switching a machine from one core size to another requires tooling changes, which can cause downtime.

- Maintenance: Automated systems require regular maintenance to keep sensors and servos running smoothly.

Industry Trends Driving Automation

Why are more manufacturers moving toward automation? It isn’t just about speed; it’s about the changing demands of the market.

The Rise of Energy Recovery

We are seeing a massive push for energy recovery systems in industrial and commercial sectors. These systems often require large, complex heat exchangers to capture waste heat. Building these massive cores by hand is difficult and dangerous. Automation allows for larger, heavier cores to be built safely.

EV Thermal Management

Electric vehicles (EVs) require incredibly efficient cooling for batteries and power electronics. The tolerances for EV heat exchangers are tighter than traditional radiators. The industry is demanding thinner materials and higher fin densities to save weight. Handling these delicate, high-density components by hand often results in damage, making automated handling a necessity rather than a luxury.

Micro-Channel Technology

The shift toward micro-channel (flat tube) heat exchangers is accelerating. These tubes are much harder to handle manually than traditional round or oval tubes. Automated core builders are specifically designed to manage the flat geometry without crushing the internal channels.

Livernois Engineering Solutions

When it comes to bridging the gap between manual flexibility and automated speed, Livernois Engineering has been a consistent leader. Their equipment is designed with the understanding that manufacturers often need to handle a mix of high-volume and high-mix production.

Core Builders for Every Stage

Livernois offers a range of core assembly machines tailored to different needs. Their systems are known for robust construction and intelligent controls.

- Semi-Automatic Builders: These are excellent for shops that need to speed up production but still run a high mix of part numbers. They automate the compression and header installation but allow for manual stacking adjustments.

- Fully Automated High-Speed Lines: For OEM suppliers producing thousands of units a day, Livernois provides integrated lines that take raw tubes and fins and output fully squared, headed cores ready for the furnace.

Beyond the Build: Ancillary Equipment

Livernois doesn’t just stop at stacking. They provide the critical ancillary support that makes the core builder effective:

- Fin Handling Systems: Automated trays and decoilers that feed the builder continuously.

- Braze Fixturing: Custom-designed fixtures that hold the core perfectly during the thermal expansion of the brazing process.

[Suggested Video: A 30-second timelapse showing a Livernois machine stacking a core, compressing it, and installing headers.]

Conclusion

Mastering the core assembly process is about matching your capabilities to your market. If you are a custom shop doing repair work or prototypes, manual processes might serve you well. But as soon as volume increases or quality requirements tighten, the move to automation becomes inevitable.

The right core assembly machine doesn’t just build parts faster; it builds confidence. It ensures that every heat exchanger leaving your facility meets the rigorous standards your customers expect.

Ready to upgrade your assembly line?

Evaluate your current cycle times and scrap rates. If you see bottlenecks in stacking or inconsistencies in header fitment, it might be time to explore automated solutions.